Process

Each metal component is manufactured in the workshop equipped with machinery and presses with high production capacity and skilled personnel.

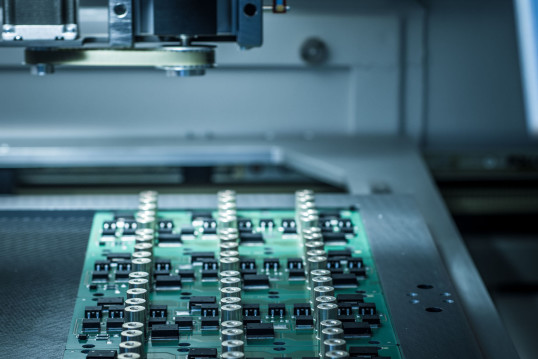

Assembly Of Electronic Components

The assembly of electronic components is realized in highly specialized departments, equipped with special automated machines and reflow ovens (including vacuum) that meet strict production standards.

Assembly Of Products

The assembly of Raddital products is realized with equipment designed and built by our technicians: that’s the result of the experience gained in 40 years of presence on the market.

Testing

At this delicate and essential stage we carry out several tests on the entire production that ensure the established functionality without the possibility of error.

Finishing

The finishing process of Raddital products is completed by inserting supports, accessories and every detail required by the client, including the surface finish for weathering protection or to ensure greater isolation.

Delivery

Raddital guarantees a quick and very accurate service, thanks to our warehouses located in different countries of the world and equipped to ensure a proper service and the certainty of our proximity